|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Note: This article is based on the 2020 NEC.

Are you able to accurately apply the overvoltage protection requirements?

Figure 01

|

|

|

Figure 01

|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Note: This article is based on the 2020 NEC.

Are you able to accurately apply the overvoltage protection requirements?

The requirements for overvoltage protection are in Article 242. This article is new with the 2020 NEC, and it replaces Articles 280 and 285. Those articles provided, respectively, the requirements for surge arrestors over 1,000V and surge-protective devices (SPDs) 1,000V or less.

So now in the arrangement of the NEC overvoltage protection comes right after overcurrent protection (Article 240).

Not only is this entire article new, it's only two pages long. That's slightly less than the combined length of Articles 280 and 285 in the 2017 NEC.

Though it's short, Article 242 is divided into three Parts:

- Part I provides the general requirements, installation requirements, and connection requirements for overvoltage protection and overvoltage protective devices, and for surge protective devices (SPDs).

- Part II covers SPDs that are rated 1kV or less that are permanently installed on premises wiring systems.

- Part III covers surge arresters permanently installed on premises wiring systems over 1,000V, nominal.

Transient voltages

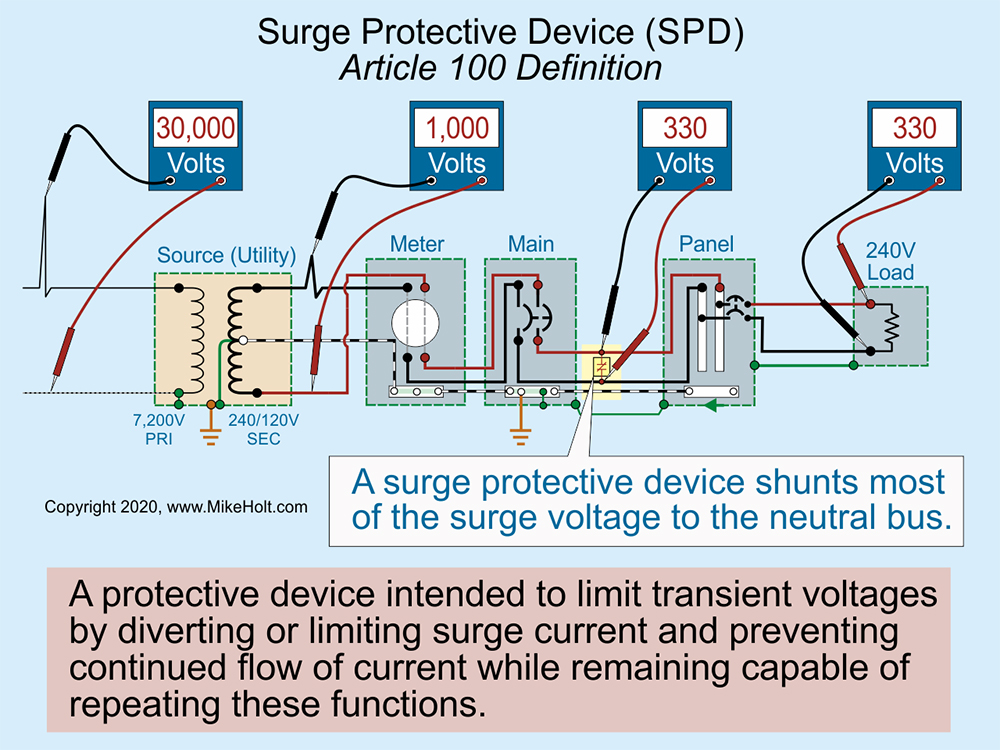

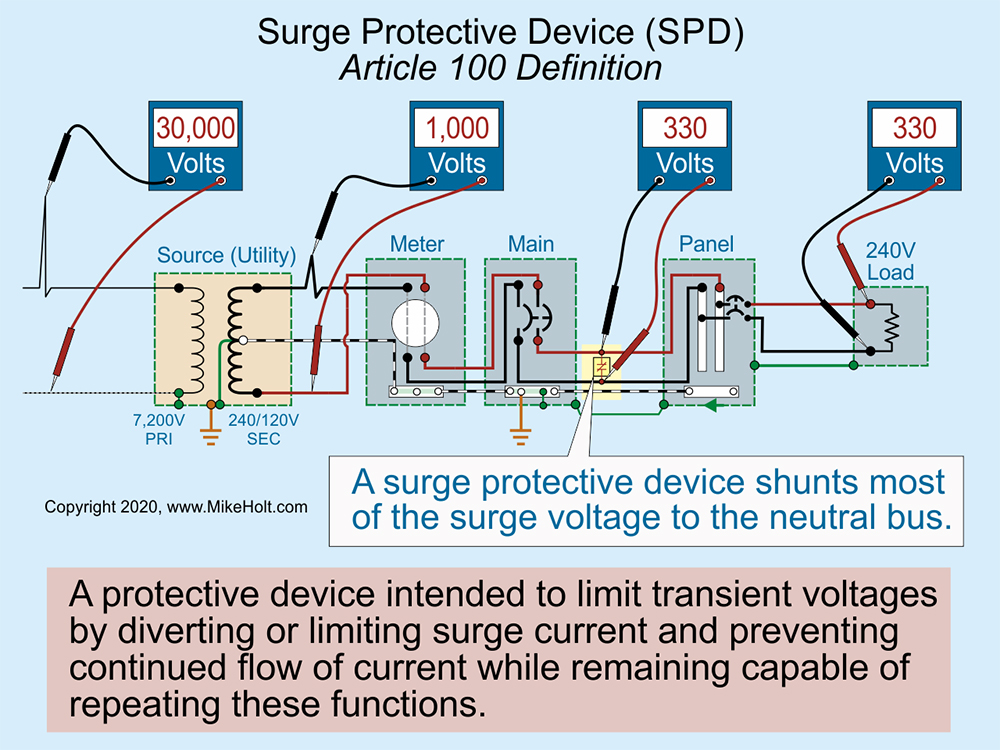

Article 100 defines an SPD as a protective device intended to limit transient voltages by diverting or limiting surge current and preventing continued flow of current while remaining capable of repeating these functions. Figure 01

SPDs are designed to reduce transient voltages (short-lived spikes of voltage) present on premises power distribution wiring and load-side equipment, including electronic equipment such as computers, telecommunications equipment, security systems, and electronic appliances.

Harmful transient voltages can originate from several sources, including lightning at one end and laser printers at the other. Voltage transients caused by the switching of utility power lines, power factor correction capacitors, or lighting can reach thousands of volts and amperes.

Voltage transients produced by premises equipment such as photocopiers, laser printers, and other high reactive loads cycling off can be in the hundreds of volts.

In manufacturing plants, large motors starting across the line are common source of transient voltages. When it's determined that equipment has been failing from these transients, the typical response is to assume the transients are coming in from the outside (perhaps dirty power from the utility). Much time is wasted trying to address a cause that does not exist.

To see what is actually going on, you could connect a portable power analyzer to the supply of each large motor or connect a power monitor to the largest loads. But if you have large motors starting across the line, you don't need to analyze anything to know they are generating transients into power distribution system. Installing a soft starter or variable frequency drive (VFD) is an effective way to fix that problem at its source.

A big fire pump that starts across the line is a typical transient source. Setting it up with a soft starter entails many special considerations. For example, most authority having jurisdiction (AHJs) will require a manual bypass so the pump can always be started if needed. Also, ensure the fire pump isn't cycling on and off due to jockey pump problems or non-emergency use.

SPDs

Ideally, you will identify sources of transients and correct for them. But that's not always possible. While you can, for example, install a soft starter on a big motor, you can't do that on a laser printer.

Having a dedicated transformer, panel, and branch circuits for transient-generating loads will help protect all other loads. But this measure doesn't take the transients out of the circuits supplying the transient-generating loads, so you need SPDs.

An SPD limits transients by either diverting the excess current or actually absorbing it. It prevents continued flow of follow current, also. And unlike a fuse, the SPD remains capable of repeating its protection. [Article 100].

For more than adequate transient protection, install SPDs in a tiered system. The tier is defined by the electrical layer in relation to the service entrance. So you'd install one type of SPD at the service entrance. It would knock down transients to an acceptable voltage level (but not entirely eliminate them). This would be a Type 1 SPD (we'll discuss the types momentarily).

At each feeder, you would have the next lower SPD. This would be a Type 2 SPD. At each branch circuit panel, you would have an even lower energy level of SPD; this is a Type 3. And you might have a still lower SPD at utilization equipment.

Why this tiered approach? It has to do with how much energy an SPD can dissipate, at what voltage it can clamp, and other performance metrics based on the physics involved. As you move electrically farther from the service, the SPDs have less transient to dissipate or divert.

An SPD cannot be used [242.6]:

(1) In circuits that exceed 1,000V.

(2) In ungrounded systems, impedance grounded systems, or corner-grounded delta systems, unless listed specifically for use on these systems.

(3) If the voltage rating of the SPD is less than the maximum continuous phase-to-ground voltage available at the point of connection.

SPDs:

- Must be listed [242.8]. According to UL 1449, Standard for SPDs, these units are intended to limit the maximum amplitude of transient voltage surges on power lines to specified values. They are not intended to function as lightning arresters or power filters.

- Must be marked with their short-circuit current rating. Don't install an SDP if its rating is less than the available fault current. This short-circuit current marking requirement does not apply to receptacles containing SPD protection [242.10].

- Are susceptible to failure at high fault currents. A hazardous condition is present if the short-circuit current rating of an SPD is less than the available fault current.

Using an SPD on just one or two phases is a waste of money that gives a false appearance of protection. So when you use SPDs, you must connect the device(s) to each phase conductor of the circuit [242.20].

You can install SPDs indoors or outdoors. You must make them inaccessible to unqualified persons, unless they are listed for installation in accessible locations [242.22].

Don't make your SPD conductors any longer than necessary, and avoid unnecessary bends [242.24]. Also avoid sharp bends. Shorter conductors and minimal bends will improve the performance of the SPD by helping to reduce conductor impedance during high-frequency transient events.

Types of SPDs

The NEC is concerned with three types of SPDs: Type 1 (services), Type 2 (feeders), and Type 3 (branch circuits). The are progressively smaller in the energy level they handle. You may also have SPDs incorporated into equipment or as stand-alone point of use protection devices.

The Type 1 SPD is a permanently connected SPD listed for installation on the supply side of the service disconnect [100]. And that's where it's typically installed.

You can connect a Type 1 SPD on the [242.12(A)]:

(1) Supply side of the service disconnect [230.82(4)].

(2) Load side of the service disconnect if you follow the rules for a Type 2 disconnection as provided in 242.14.

When installed at the service disconnect, Type 1 SPDs must be connected to one of the following [242.12(B)]:

(1) Service neutral conductor.

(2) Grounding electrode conductor.

(3) Grounding electrode for the service.

(4) Equipment grounding terminal in the service equipment.

As with any other kind of terminal connection, only one conductor can be connected to a terminal unless the terminal is identified for multiple conductors [110.14(A)]. This holds true for the Type 2 and Type 3 SPD, as well.

The Type 2 SPD is a permanently connected SPD listed for installation on the load side of the service disconnect. While you can use a Type 1 SPD on either side of the service disconnect, you can use a Type 2 only on the load side [242.14(A)].

For feeder-supplied buildings, Type 2 SPDs must be connected somewhere on the load side of the building overcurrent device [242.14(B)]. You can connect Type 2 SPDs anywhere on the premises wiring of the separately derived system [242.14(C)].

A Type 3 SPD is an SPD listed for installation on branch circuits [100].

You can install Type 3 SPDs on the load side of a branch-circuit overcurrent protective device [242.16]. If included in the manufacturer's instructions, the Type 3 SPD connection must be a minimum 30 ft of conductor distance from the service or transformer disconnect.

Keeping perspective

SPDs should be part of an overall strategy for providing clean power to utilization equipment. They are additional protection, not primary protection. They are not a substitute for a properly implemented lightning protection system. Nor are they intended to make up for poor design, poor installation, bonding deficiencies, or failure to mitigate transient generation problems within load side distribution.

Merely following the NEC minimum requirements will get you a safe installation, not necessarily one that provides the desired performance. For optimum protection, engineer your SPD implementation with the same care you use to engineer your power distribution implementation.

|