- About Us

- Contact Us

- Testimonials

- Continuing Education

- Approved Courses

- Course Login

- Electrical Engineer PDHs

- ICC Approved Courses

- Live CEU Seminars

- NABCEP CEUs

- Electrical Engineering

- Electrical Engineer PDHs

- Engineers Library

- Exam Preparation

- Florida State Exam Prep

- Inspector (Electrical)

- Journeyman Exam Prep

- Masters Exam Prep

- State Licensing Boards

- Free Stuff

- Charts & Calculators

- Code Forum

- Find an Expert

- Find a School

- Graphic of the Day

- Job Board

- Links

- NEC

- Newsletters

- Publications

- Podcasts

- Technical

- Videos

- Instructors & Schools

- Apprenticeship

- Capacitor Login

- ISBNs

- Training Solutions

- Request a Quote

- Products

- Best Values

- Books & DVDs

- Clearance

- Seminars

- CEU Seminars

- Seminar Schedule

Technical Resources

FREERESOURCES

We strive to provide the electrical industry with resources that will guide , inspire and educate you to become the best that you can be. Our goal with this page is to make it easy for you to find the information that you need in one place. Remember, when it comes to things electrical, don’t guess or think—research, learn and make sure that you have the FACTS.

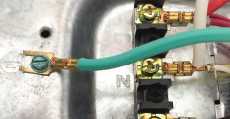

Bonding & Grounding

Articles, Code Forum, newsletters and videos

Business Management

Articles, Code Forum, newsletters

Calculations

Articles, Code Forum, newsletters and videos

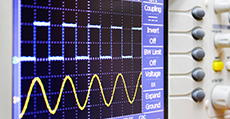

Electrical Theory

Code Forum and videos

Engineering

Articles, Code Forum and links

Estimating

Code Forum and estimating software

Lightning/ Surge Protection

Articles, Code Forum, links and newsletters

Low Voltage

Code Forum, links and newsletters

Marinas & Boatyards

Articles, newsletters and resources

National Electrical Code

Code Forum, newsletters, NEC questions, state adoptions and videos

Power Quality

Articles, Code Forum, links and newsletters

Safety

Articles, Code Forum, links, newsletters and videos

Solar Photovoltaics

Code Forum, links, newsletters and videos

Stray Voltage

Articles, Code Forum, links, newsletters and videos

Swimming Pools

How to verify the electrical system of a pool is safe in accordance with the NEC

Underwriters Laboratories

UL Articles