|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

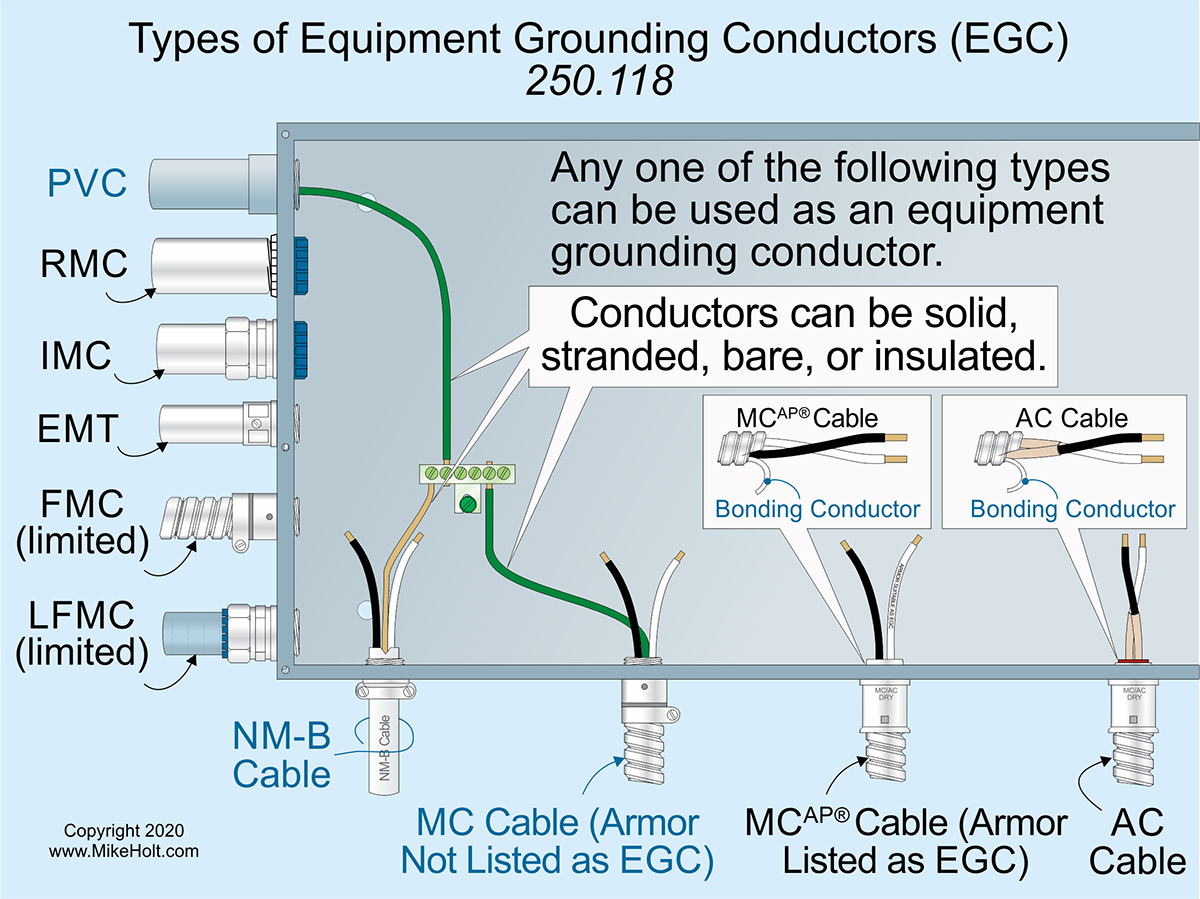

Know the types of equipment grounding conductors, and how equipment grounding conductors must be identified.

Figure 01

|

|

|

Figure 01

|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

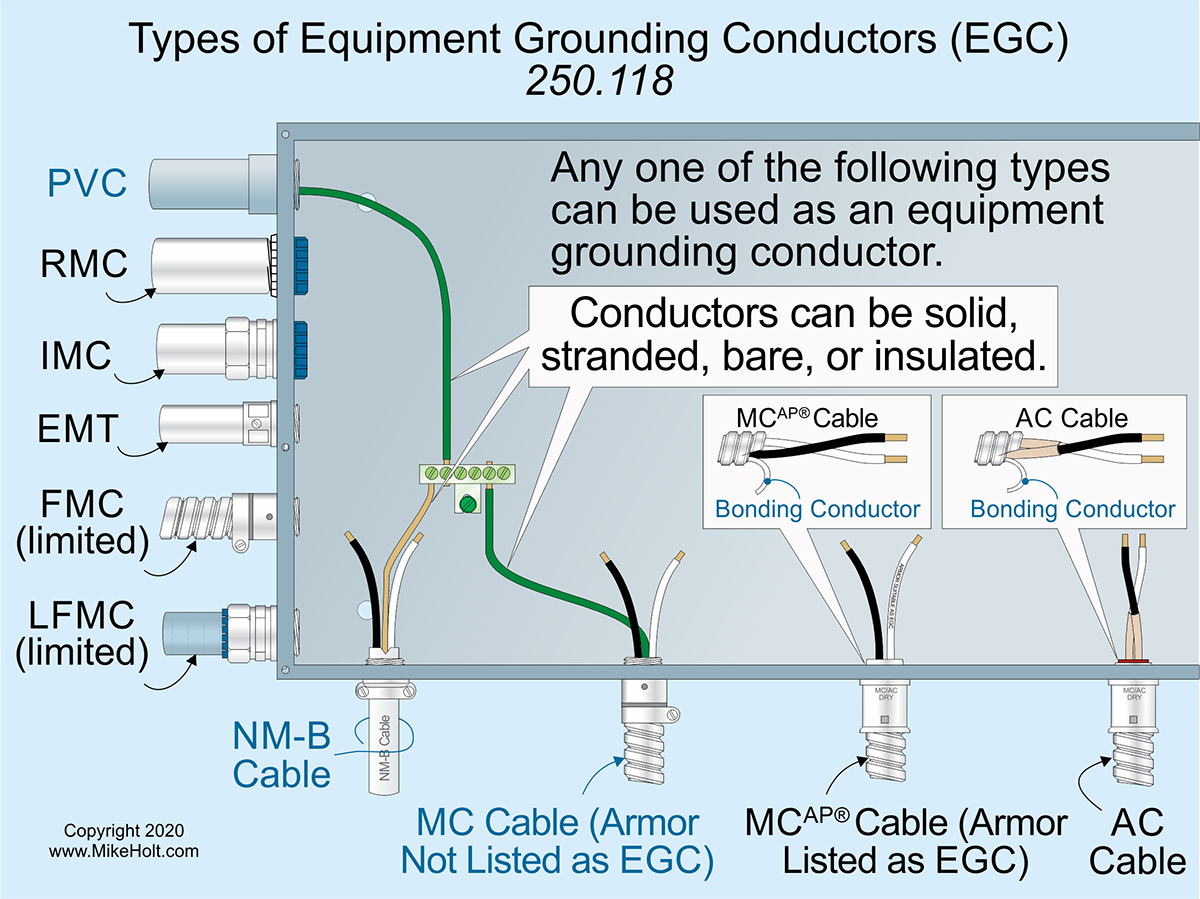

Know the types of equipment grounding conductors, and how equipment grounding conductors must be identified.

The equipment grounding conductor (EGC) serves as part of the effective ground-fault current path [Article 100].

The effective ground-fault current path [Article 100] is an intentionally constructed low-impedance conductive path designed to carry fault current from the point of a ground fault on a wiring system to the electrical supply source. If correctly installed, the EGC will quickly remove dangerous voltage from a ground fault by opening the circuit overcurrent protective device (OCPD).

The EGC can be any one of the following types [250.118]: Figure 01

(1) A bare or insulated copper, aluminum, or copper-clad aluminum conductor sized per 250.122.

(2) Rigid metal conduit.

(3) Intermediate metal conduit.

(4) Electrical metallic tubing.

(5) Listed flexible metal conduit where:

a. The raceway terminates in listed fittings.

b. The circuit conductors are protected by an overcurrent device rated 20A or less.

c. The size of the flexible metal conduit does not exceed 1¼.

d. The combined length of the flexible metal conduit in the same effective ground-fault current path does not exceed 6 ft.

e. If flexibility is required to minimize the transmission of vibration from equipment or to provide flexibility for equipment that requires movement after installation, an EGC of the wire type must be installed with the circuit conductors per 250.102(E).

(6) Listed liquidtight flexible metal conduit where:

a. The raceway terminates in listed fittings.

b. For 38 in. through ½ in., the circuit conductors are protected by OCPDs rated 20A or less.

c. For ¾ in. through 1¼ in., the circuit conductors are protected by OCPDs rated 60A or less.

d. The combined length of the liquidtight flexible metal conduit in the same effective ground-fault current path does not exceed 6 ft.

e. If flexibility is required to minimize the transmission of vibration from equipment or to provide flexibility for equipment that requires movement after installation, an EGC of the wire type must be installed with the circuit conductors per 250.102(E).

(8) The sheath of Type AC cable.

The internal aluminum bonding strip is not an EGC, but it allows the interlocked armor of Type AC cable to serve as an EGC because it reduces the impedance of the armored spirals. It is the aluminum bonding strip in combination with the cable armor that creates the circuit EGC. Once the bonding strip exits the cable, it can be cut off because it no longer serves any purpose.

(10) Type MC cable:

a. That contains an insulated or uninsulated EGC of the wire type.

b. Where the metallic sheath and uninsulated equipment grounding/bonding conductor is listed and identified as an EGC.

This type of MC cable (Type MCAP®) has an aluminum bonding strip in intimate contact with the metal sheath to serve as the EGC and can be cut off once it exits the cable. The effective ground-fault current path must be maintained by the use of fittings specifically listed for Type MCAP® cable [330.6]. See 300.12, 300.15, and 330.108.

c. When the metallic sheath of smooth or corrugated tube-type MC cable is listed and identified as an EGC, it can serve as an EGC.

(11) Metal cable trays if continuous maintenance and supervision ensure only qualified persons will service the cable tray; the cable tray and fittings are identified for grounding; and the cable tray, fittings [392.10], and raceways are bonded together using bolted mechanical connectors or bonding jumpers sized and installed per 250.102 [392.60].

(13) Other listed electrically continuous metal raceways such as metal wireways [Article 376] or strut-type channel raceways [384.60].

(14) Surface metal raceways listed for grounding [Article 386].

Listed offset nipples and metal fittings for metal cable, conduit, and tubing are considered suitable for grounding circuits where installed per the NEC, except as noted for flexible metal conduit fittings and liquid-tight flexible metal conduit fittings. See UL Product Spec Guide, Information for Conduit Fittings (DWTT).

EGC Identification

Unless the NEC requires a specific EGC to be insulated, an EGC can be bare or covered. But either way, every EGC must be identified per the requirements of 250.119.

Insulated EGCs 6 AWG and smaller must have a continuous outer finish that is either green or green with one or more yellow stripes.

Conductors with insulation that is green, or green with one or more yellow stripes, are not permitted to be used for a phase or neutral conductor. The NEC neither requires nor prohibits the use of the color green for the identification of grounding electrode conductors.

(A) Conductors 4 AWG and larger

(1) Identified where accessible. Insulated EGCs 4 AWG and larger can be reidentified at the time of installation where the conductor is accessible.

(2) Identification methods. Identification must encircle the conductor and be accomplished by:

a. Removing the conductor insulation.

b. Coloring the insulation green at termination.

c. Marking the insulation at termination with green tape or green adhesive labels.

(B) Multiconductor cable

One or more insulated conductors in a multiconductor cable, at the time of installation, are permitted to be permanently identified as EGCs at each end and at every point where the conductors are accessible by one of the following means:

(1) Stripping the insulation from the entire exposed length.

(2) Coloring the exposed insulation green.

(3) Marking the exposed insulation with green tape or green adhesive labels. Identification must encircle the conductor.

Metal enclosures

You can use metal enclosures to connect bonding jumpers or equipment grounding conductors (EGCs) or both together to become part of an effective ground-fault current path [250.109].

Metal covers and metal fittings attached to these metal enclosures are considered as being connected to bonding jumpers or EGCs, or both. Think about that the next time you remove a cover.

Cord-and-plug-connected equipment

Exposed, normally noncurrent-carrying metal parts of cord-and-plug-connected equipment must be connected to the EGC of the circuit supplying the equipment under any of the following conditions [250.114].

(But there is an exception. Listed tools, listed appliances, and listed equipment covered in 250.114(2) through (4) are not required to be connected to an EGC where protected by a system of double insulation or its equivalent. Double insulated equipment must be distinctively marked.)

(1) In hazardous (classified) locations [Articles 500 through 517].

(2) Where operated at over 150V to ground.

Ex 1 to (2): Motors that are guarded.

Ex 2 to (2): Metal frames of exempted electrically heated appliances.

(3) In residential occupancies:

a. Refrigerators, freezers, and air conditioners.

b. Clothes-washing, clothes-drying, and dish-washing machines; ranges; kitchen waste disposers; IT equipment; sump pumps; and electrical aquarium equipment.

Electric ranges and clothes dryers are shipped from the factory with a bonding strap that bonds the metal frame of the appliance to the neutral termination of the cord connection terminal block. GFCI protection is now required for 250V receptacles in accordance with 210.8(A), therefore any neutral to ground connections will immediately cause the GFCI device to trip.

This bonding strap may or may not have to be removed! The Code requires an insulated neutral for these appliances using a 4-wire branch circuit and the bonding strap should be removed. However, if an existing 3-wire branch circuit is to supply a replacement appliance, the factory-installed bonding strap must remain in place [250.140 Ex].

c. Hand-held, stationary or fixed, and light industrial motor-operated tools.

d. Motor-operated hedge clippers, lawn mowers, snow-blowers, and wet scrubbers.

e. Portable handlamps and portable luminaires.

(4) In other than residential occupancies:

a. Refrigerators, freezers, and air conditioners.

b. Clothes-washing, clothes-drying, and dish-washing machines; IT equipment; sump pumps; and electrical aquarium equipment.

c. Hand-held, stationary or fixed, and light industrial motor-operated tools.

d. Motor-operated hedge clippers, lawn mowers, snow-blowers, and wet scrubbers.

e. Portable handlamps and portable luminaires.

f. Appliances used in damp or wet locations or by persons standing on the ground, standing on metal floors, or working inside of metal tanks or boilers.

g. Tools likely to be used in wet or conductive locations

Ex: Tools and portable handlamps and portable luminaires likely to be used in wet or conductive locations do not have to be connected to an EGC where supplied through an isolating transformer with an ungrounded secondary not over 50V.

Is your EGC AOK?

A common problem in understanding EGC design and construction is the myth that electricity takes the least path of resistance. If this myth were true, none of our electronics would work. They all depend upon Kirchhoff's Law of Parallel Circuits. Electricity flows in inverse proportion to the impedances presented to it.

Without a good EGC, the time for a fault to clear will be long or even worse, not at all. Perhaps too long to prevent a catastrophe. A properly constructed EGC system is crucial for protecting people and property from the hazards of electricity.

|