|

|

| NEC Questions and Answers - July 2015 - Based on the 2014 NEC | |

|

|

|

|

By Mike Holt for EC&M Magazine Here's the follow up to yesterday's newsletter. This includes all of the answers to the questions sent, so you can see how you did.

Note: These questions are based on the 2014 NEC®. Any underlined text indicates a change to the Code rule for the 2014 NEC.

Q1. What are the rules for grounding and bonding transformers? A1. Separately derived systems must be grounded and bonded in accordance with 250.30(A)(1) through (A)(8). A neutral-to-case connection must not be made on the load side of the system bonding jumper, except as permitted by 250.142(B). A system bonding jumper must be installed at the same location where the grounding electrode conductor terminates to the neutral terminal of the separately derived system; either at the separately derived system or the system disconnecting means, but not at both locations [250.30(A)(1) and (5)]. Where the system bonding jumper is installed at the source of the separately derived system, the system bonding jumper must connect the neutral conductor of the derived system to the metal enclosure of the derived system [250.30(A)(1)(a)]. Where the system bonding jumper is installed at the first disconnecting means of a separately derived system, the system bonding jumper must connect the neutral conductor of the derived system to the metal disconnecting means enclosure [250.30(A)(1)(b)].

A supply-side bonding jumper (nonflexible metal raceway or wire) must be run from the derived system to the derived system disconnecting means [250.30(A)(2)]. If the supply-side bonding jumper is of the wire type, it must be sized in accordance with Table 250.102(C)(1), based on the area of the largest ungrounded derived system conductor in the raceway or cable [250.30(A)(2)(a)].

(a) The neutral conductor must be routed with the ungrounded conductors of the derived system to the disconnecting means and be sized not smaller than specified in Table 250.102(C)(1), based on the area of the ungrounded conductor of the derived system. (b) If the conductors from the derived system are installed in parallel in two or more raceways, the neutral conductor of the derived system in each raceway or cable must be sized not smaller than specified in Table 250.102(C)(1), based on the area of the largest ungrounded conductor of the derived system in the raceway or cable. In no case is the neutral conductor of the derived system permitted to be smaller than 1/0 AWG [310.10(H)].

The grounding electrode for a separately derived system must be as near as practicable, and preferably in the same area where the system bonding jumper is installed and be one of the following [250.30(A)(4)]: (1) Metal water pipe electrode, within 5 ft of the entry to the building [250.52(A)(1)]. (2) Metal building frame electrode [250.52(A)(2)].

Note 1: Interior metal water piping in the area served by separately derived systems must be bonded to the separately derived system in accordance with 250.104(D). When sizing the grounding electrode conductor for a single separately derived system, the grounding electrode conductor must be sized in accordance with 250.66, based on the area of the largest ungrounded conductor of the derived system. A grounding electrode conductor must terminate to the neutral at the same point on the separately derived system where the system bonding jumper is connected [250.30(A)(5)].

Ex 1: The grounding electrode conductor is permitted to terminate to the equipment grounding terminal at the derived system or first system disconnecting means in accordance with 250.30(A)(1). Ex 3: Separately derived systems rated 1 kVA or less aren’t required to be grounded (connected to the earth). Where there are multiple separately derived systems, a grounding electrode conductor tap from each separately derived system to a common grounding electrode conductor is permitted [250.30(A)(6)]. This connection is to be made at the same point on the separately derived system where the system bonding jumper is connected [250.30(A)(1)]. Ex 1: If the system bonding jumper is a wire or busbar, the grounding electrode conductor tap can terminate to either the neutral terminal or the equipment grounding terminal, bar, or bus in accordance with 250.30(A)(1). Ex 2: Separately derived systems rated 1 kVA or less aren’t required to be grounded (connected to the earth). The common grounding electrode conductor can be one of the following [250.30(A)(6)(a)]: (1) A conductor not smaller than 3/0 AWG copper or 250 kcmil aluminum. (2) The metal frame of the buildings that complies with 250.52(A)(2) or is connected to the grounding electrode system by a conductor not smaller than 3/0 AWG copper or 250 kcmil aluminum. Grounding electrode conductor taps must be sized in accordance with Table 250.66, based on the area of the largest ungrounded conductor of the given derived system [250.30(A)(6)(b)]. All tap connections to the common grounding electrode conductor must be made at an accessible location by one of the following methods [250.30(A)(6)(c)]: (1) A connector listed as grounding and bonding equipment. (2) Listed connections to aluminum or copper busbars not less than ¼ in. in depth x 2 in. in width (3) Exothermic welding. Grounding electrode conductor taps must be connected to the common grounding electrode conductor so the common grounding electrode conductor isn’t spliced. The grounding electrode conductor must comply with the following [250.30(A)(7)]:

To ensure dangerous voltage from a ground fault is removed quickly, structural steel and metal piping in the area served by a separately derived system must be connected to the neutral conductor at the separately derived system in accordance with 250.104(D) [250.30(A)(8)]. Separately derived systems located outside the building must have the grounding electrode connection made at the separately derived system location [250.30(C)].

Q2. What are the Code rules for grounding and bonding service equipment? A2. Service equipment supplied from a grounded system must have the grounding electrode conductor terminate in accordance with 250.24(A)(1) through (5). (1) A grounding electrode conductor must connect the service neutral conductor to the grounding electrode at any accessible location, from the load end of the overhead service conductors, service drop, underground service conductors, or service lateral, up to and including the service disconnecting means.

(4) When the service neutral conductor is connected to the service disconnecting means [250.24(B)] by a wire or busbar [250.28], the grounding electrode conductor is permitted to terminate to either the neutral terminal or the equipment grounding terminal within the service disconnect. (5) A neutral-to-case connection isn’t permitted on the load side of service equipment, except as permitted by 250.142(B).

A main bonding jumper [250.28] is required to connect the neutral conductor to the equipment grounding conductor within the service disconnecting means [250.24(B)].

Q3. What are the rules in using the neutral conductor for bonding of metal parts? A3. For service equipment: The neutral conductor can be used as the circuit equipment grounding conductor on the supply side or within the enclosure of the service disconnect in accordance with 250.24(B) [250.142(A)(1)]. For separately derived systems: The neutral conductor can be used as the circuit equipment grounding conductor at the source of a separately derived system or within the enclosure of the system disconnecting means in accordance with 250.30(A)(1) [250.142(A)(3)].

Except as permitted in 250.30(A)(1) for separately derived systems and 250.32(B) Ex, for separate buildings/structures, the neutral conductor isn’t permitted to serve as an equipment grounding conductor on the load side of service equipment [250.142(B)]. Ex 1: In existing installations, the frames of ranges, wall-mounted ovens, counter-mounted cooking units, and clothes dryers can be connected to the neutral conductor in accordance with 250.140 Ex. Ex 2: The neutral conductor can be connected to meter socket enclosures on the load side of the service disconnecting means if: (1) Ground-fault protection isn’t provided on service equipment, (2) Meter socket enclosures are immediately adjacent to the service disconnecting means, and (3) The neutral conductor is sized in accordance with 250.122, based on the ampere rating of the occupancy’s feeder overcurrent device.

Q4. What are the rules for receptacle replacement? A4. When replacing receptacles, remember that arc-fault circuit-interrupter type and ground-fault circuit interrupter type receptacles must be installed at a readily accessible location [406.4(D)]. If an equipment grounding conductor exists, grounding-type receptacles must replace nongrounding-type receptacles and the receptacle’s grounding terminal must be connected to the circuit equipment grounding conductor in accordance with 250.130(C) or 406.4(C) [406.4(D)(1)]. If an equipment grounding conductor doesn’t exist in the outlet box, the existing nongrounding-type receptacles can be replaced with [406.4(D)(2)]: (a) A nongrounding-type receptacle. (b) A GFCI-type receptacle marked “No Equipment Ground.” (c) A grounding-type receptacle, if GFCI protected and marked “GFCI Protected” and “No Equipment Ground.”

When existing receptacles are replaced in locations where GFCI protection is currently required, the replacement receptacles must be GFCI protected [406.4(D)(3)].

Effective January 1, 2014, where a receptacle outlet is supplied by a branch circuit that requires arc-fault circuit-interrupter protection [210.12(A)], a replacement receptacle at this outlet must be one of the following [406.4(D)(4)]: (1) A listed (receptacle) outlet branch-circuit type arc-fault circuit-interrupter receptacle. (2) A receptacle protected by a listed (receptacle) outlet branch-circuit type arc-fault circuit-interrupter type receptacle. (3) A receptacle protected by a listed combination type arc-fault circuit interrupter type circuit breaker. Listed tamper-resistant receptacles must be provided where replacements are made at receptacle outlets that are required to be tamper resistant in accordance with 406.12 for dwelling units, guest rooms and guest suites, and child care facilities [406.4(D)(5)]. Weather-resistant receptacles must be provided where replacements are made at receptacle outlets that are required to be so protected in accordance with 406.9(A) and (B) [406.4(D)(6)].

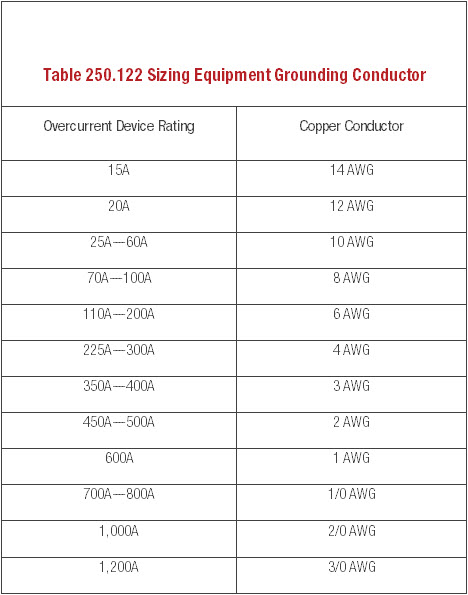

Q5. What are the rules in sizing equipment grounding conductors? A5. Equipment grounding conductors of the wire type must be sized not smaller than shown in Table 250.122, based on the rating of the circuit overcurrent device; however, the circuit equipment grounding conductor isn’t required to be larger than the circuit conductors [250.122(A)].

If ungrounded conductors are increased in size from the minimum ampacity that’d be required for the load, wire type equipment grounding conductors must be proportionately increased in size according to the circular mil area of the ungrounded conductors [250.122(B)].

When multiple circuits are installed in the same raceway, cable, or cable tray, one equipment grounding conductor sized in accordance with 250.122, based on the rating of the largest circuit overcurrent device is sufficient [250.122(C)]. For motor branch circuits, The equipment grounding conductor of the wire type must be sized in accordance with Table 250.122, based on the rating of the motor circuit branch-circuit short-circuit and ground-fault overcurrent device [250.122(D)], but this conductor isn’t required to be larger than the circuit conductors [250.122(D)(1)].

If circuit conductors are installed in parallel in separate raceways or cable as permitted by 310.10(H), an equipment grounding conductor must be installed for each parallel conductor set [250.122(F)]. The equipment grounding conductor in each raceway or cable must be sized in accordance with Table 250.122, based on the rating of the circuit overcurrent device, but it’s not required to be larger than the circuit conductors [250.122(A)]. Equipment grounding conductors for feeder taps must be sized in accordance with Table 250.122, based on the ampere rating of the overcurrent device ahead of the feeder, but in no case is it required to be larger than the feeder tap conductors [250.122(G)].

Q6. What are the GFCI protection requirements for receptacles? A6. Ground-fault circuit interruption for personnel must be provided as required in 210.8(A) through (D). The ground-fault circuit-interrupter device must be installed at a readily accessible location.

GFCI protection is required for 15A and 20A, 125V receptacles installed in the following locations in dwelling units [210.8(A)]:

GFCI protection is required for 15A and 20A, 125V receptacles in the bathroom area of a dwelling unit [210.8(A)(1)].

GFCI protection is required for 15A and 20A, 125V receptacles in garages, and in grade-level portions of accessory buildings used for storage or work areas of a dwelling unit [210.8(A)(2)].

15A and 20A, 125V receptacles located outdoors of dwelling units, including receptacles installed under the eaves of roofs, must be GFCI protected [210.8(A)(3)].

Ex: GFCI protection isn’t required for a receptacle that’s supplied by a branch circuit dedicated to fixed electric snow-melting or deicing or pipeline and vessel heating equipment, if the receptacle isn’t readily accessible and the equipment or receptacle has ground-fault protection of equipment (GFPE) [426.28 and 427.22]. 15A and 20A, 125V receptacles installed in crawl spaces at or below grade of a dwelling unit must be GFCI protected [210.8(A)(4)].

GFCI protection is required for 15A and 20A, 125V receptacles located in the unfinished portion of a basement not intended as a habitable room and limited to storage and work areas in dwelling units [210.8(A)(5)]. Ex: A receptacle supplying only a permanently installed fire alarm or burglar alarm system isn’t required to be GFCI protected [760.41(B) and 760.121(B)].

GFCI protection is required for 15A and 20A, 125V receptacles that serve countertop surfaces in a dwelling unit [210.8(A)(6)].

GFCI protection is required for 15A and 20A, 125V receptacles located within an arc measurement of 6 ft from the outside edge of a sink in dwelling units [210.8(A)(7)]. GFCI protection is required for all 15A and 20A, 125V receptacles located in a dwelling unit boathouse [210.8(A)(8)].

GFCI protection is required for 15A and 20A, 125V receptacles located within 6 ft of the outside edge of a bathtub or shower stall in dwelling units [210.8(A)(9)]. 15A and 20A, 125V receptacles installed in laundry areas of a dwelling unit must be GFCI protected [210.8(A)(10)]. For other than dwelling units: GFCI protection is required for 15A and 20A, 125V receptacles installed in the following commercial/industrial locations [210.8(B)]: 15A and 20A, 125V receptacles installed in commercial or industrial bathrooms must be GFCI protected [210.8(B)(1)].

15A and 20A, 125V receptacles installed in a non-dwelling kitchen, even those that don’t supply the countertop surface, must be GFCI protected [210.8(B)(2)].

15A and 20A, 125V receptacles installed on non-dwelling rooftops must be GFCI protected [210.8(B)(3)].

Ex 1 to (3): Receptacles on rooftops aren’t required to be readily accessible other than from the rooftop. 15A and 20A, 125V receptacles installed outdoors must be GFCI protected [210.8(B)(4)]. Ex 2 to (3) and (4): GFCI protection isn’t required for a receptacle that’s supplied by a branch circuit dedicated to fixed electric snow-melting or deicing or pipeline and vessel heating equipment, if the receptacle isn’t readily accessible and the equipment or receptacle has ground-fault protection of equipment (GFPE) [426.28 and 427.22]. 15A and 20A, 125V receptacles installed within 6 ft of the outside edge of a sink must be GFCI protected [210.8(B)(5)]. Ex 1: In industrial laboratories, receptacles used to supply equipment where removal of power would introduce a greater hazard aren’t required to be GFCI protected. Ex 2: Receptacles located in patient bed locations of general care or critical care areas of health care facilities aren’t required to be GFCI protected. 15A and 20A, 125V receptacles installed indoors in wet locations of non-dwelling units must be GFCI protected [210.8(B)(6)]. 15A and 20A, 125V receptacles installed in locker rooms with associated showering facilities must be GFCI protected [210.8(B)(7)]. 15A and 20A, 125V receptacles installed in non-dwelling unit garages, service bays, and similar areas must be GFCI protected, unless they’re in show rooms or exhibition halls [210.8(B)(8)]. GFCI protection is required for outlets supplying boat hoists in dwelling unit locations [210.8(C)].

Outlets supplying dishwashers in a dwelling unit must be GFCI protected [210.8(D)].

|

|||

|

|

| Visit: Exam Preparation | Continuing Education | Code Products | Newsletters | and more | |||

|

|

|||

|